TDB15W Series DC DC Converter-IDEALPLUSING

Application:

Industrial automation control

Photovoltaic power generation

Various industrial and civil fields

I. MODELS LIST

Single Channels Ouput

Models | Input voltage | Input voltage

| Output voltage and currente | Ripple and noise(mv) | Efficiency (1000Vdc) | Size(L*W*H) |

TDB15-900S32H | 1000VDC | 300-1500VDC | 32VDC/470mA | 100mV | 73% | 100*60*25mm |

II. FEATURES

1 | Ultra-wide input voltage range: 300-1500VDC |

2 | Isolated for Input and output |

3 | Input undervoltage protection, input reverse protection |

4 | Ou Output overcurrent protection, output short circuit protection |

5 | High efficiency, long life and high reliability, **** full load burn-in test |

Condition: All specifications are tested under the room temperature 25 ℃, Normal input voltage and Pure Negative Normal Load

III. INPUT CHARACTERISTIC

Item | Condition | Mini value | Typical value | Max value |

Input voltage range | DC Input | 300VDC | 1000VDC | 1500VDC |

Input current | - | - | 50mA | |

Inrush current | 300VDC | - | 30A | - |

Input undervoltage protection | Undervoltage protection point | - | 250VDC | - |

Undervoltage release point | - | 265VDC | - | |

Input anti-reverse protection | Yes | |||

IV. OUTPUT CHARACTERISTIC

Item | Condition | Mini value | Typical value | Max value |

Voltage set-point accuracy | - | ±2% | - | |

Linear regulation | Output full load | - | ±1% | - |

Load regulation | 10-**** load | - | ±1% | - |

Output ripple noise * | 20MHz bandwidth (peak to peak) | - | 100mV | 200mV |

Short circuit protection | Short circuit protected, no output | |||

Output overcurrent protection | ≥110% Io, self-recovery | |||

Minimum load | 0 | - | - | |

Start delay time | - | 5s | - | |

Power-off hold time | - | 10ms | - | |

Note: * Ripple and noise are measured by parallel line test method (oscilloscope probe is measured by putting on, and a 10μF high-frequency low-resistance electrolytic capacitor and a 0.1μF ceramic capacitor are connected in parallel).

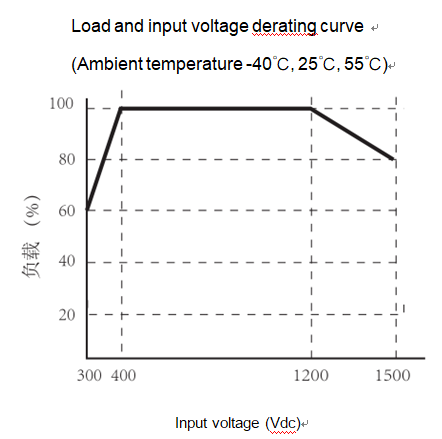

V. Curve chart

VI. Application description

1. Typical application circuit

2. EMC Solution One Recommended circuit

3. Recommended parameters

① Input part

Components | Function | Description and recommended values |

FUSE | When module is abnormal, fuse blown, module cut off | Fuse, 2KV 1A, Slow-Blow(Must) |

NTC | Suppress surge current | Negative temperature coefficient Thermistor (NTC), 5D-9 |

MOV | Absorb lightning surge | Varistor, 182KD14 |

C7 | Suppression of differential mode interference | X1 safety capacitor, using 4pcs 0.33μF capacitors in series |

L | Differential mode inductance, 330μH | |

C5,C6 | Suppression of common mode interference | Y1 safety capacitors, each using three 1000pF capacitors in series |

② Output part

Output voltage | C1 | C2 | TVS | RL |

32V | 100μF/50V | 1μF/50V | SMBJ40A | Load |

Note:

a. C1: Output filter electrolytic capacitor is recommended to use high frequency and low resistance electrolytic capacitor.

b. C2: Ceramic capacitor is to suppress high-frequency noise.

c. TVS:Transient suppression diode is protected the rear circuit and is recommended to use.

d. The output load loop can be in series with 50V 1.5A fuse when testing it.

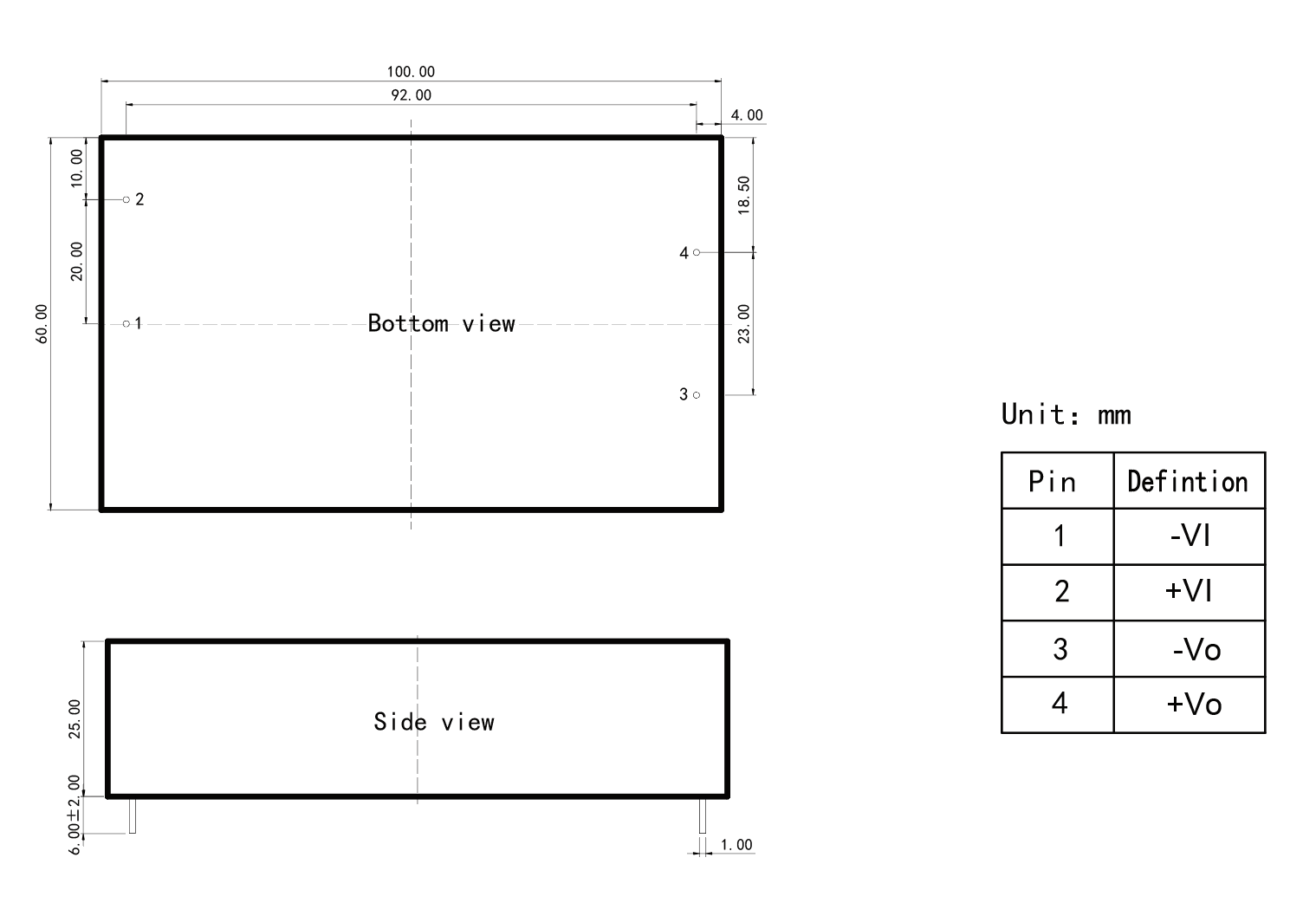

VI. Size drawing

VII. Installation and use instructions:

1. Unless specified, test conditions are as follows: ambient temperature 25℃, humidity <75%, input voltage 1000VDC and output rated load.

2. When using, please install a SPD of clamping voltage 6KV at the input terminal.

3. In order not to affect the reliability of the product, do not exceed to use the nominal value of the power supply. If you need to change the output parameters, please consult the technical department before using in order to ensure the effect and reliability.

4. If the module fails, please do not repair it by yourself. Please contact the customer service Department as soon as possible.

5. All index test methods in this manual are based on the company's standards.

VIII. Packaging, transportation, storage:

1. Packaging: There is the product name, model, manufacturer's logo, manufacturer's quality department inspection certificate, manufacturing date, etc. on the packing carton.

2. Transportation: This package is suitable for car, ship, plane, train and other transportation, the transportation process should be rainproof, civilized loading and unloading.

3. Storage: When the product is not used, it should be placed in the packing carton, the storage environment temperature and relative humidity should meet the requirements of the product. There should be no corrosive gases or products in the warehouse, and there is no strong mechanical vibration, shock and strong magnetic field. The packing carton should be placed at least 20cm above the ground and protected from water. If the storage time is too long (more than 1 year), it should be re-inspected by professionals before use.

版权所有 广东铭锌科技有限公司 备案号:粤ICP备2021171912号 技术支持:天英网络